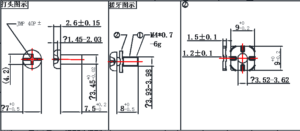

Square Washer Screw High-Grade Fasteners ASTM & DIN Standards

Size:M2-M10

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

Treatment/Finishing: Brushing、Anodizing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

In mechanical assemblies, the combination of machine screws and square washers plays a significant role in achieving optimal load distribution and structural stability. Square washers, due to their larger surface area compared to standard round washers, are particularly effective in preventing pull-through and deformation when paired with coarse or fine-thread screws. These characteristics are essential in heavy timber constructions, steel frameworks, and high-torque assemblies.

Square washers are commonly manufactured in carbon steel or stainless steel (A2, A4 grades), and are available in plain finish, zinc plated, hot-dip galvanized, or black oxide coatings, depending on the environmental conditions and corrosion resistance requirements. Most conform to DIN 436 or ASTM F844 standards, ensuring compatibility with metric and inch-based screw sizes.

TAIMING, a precision-driven manufacturer and supplier of fastening solutions, emphasizes the importance of material-grade alignment between screws and washers. Our engineering team suggests pairing Grade 8.8 or 10.9 screws with heat-treated square washers to avoid deformation under clamping pressure in structural steel applications. Moreover, in dynamic environments such as vibration-prone equipment or outdoor fixtures, TAIMING recommends square washers with chamfered edges to reduce stress concentration around the hole area and enhance fatigue resistance.

From an installation standpoint, TAIMING also notes that screws with hex, torx, or slotted drive types offer improved torque control when used with square washers, particularly on softwood or composite substrates. Their internal tests show that a mismatched hardness level between washers and screws may lead to premature loosening or washer distortion—especially when subjected to thermal cycling or impact load.