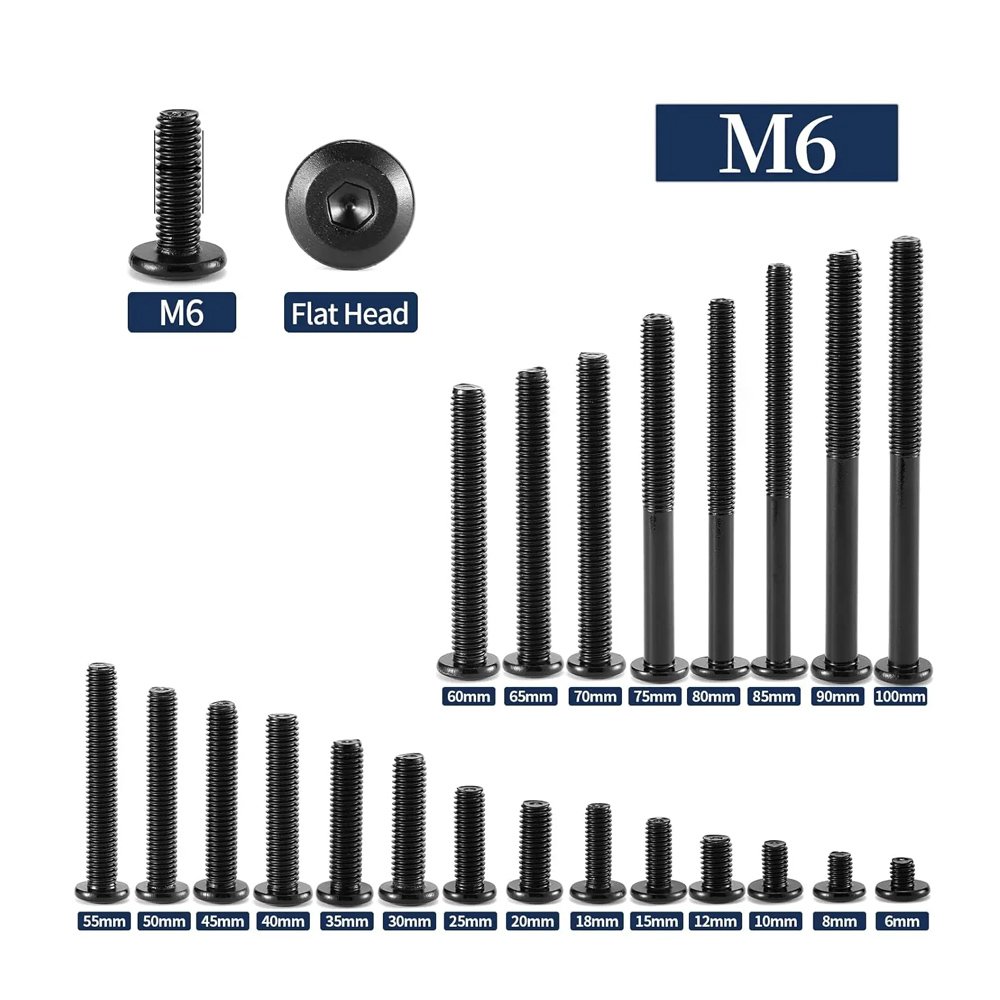

Slim Head Machine Screw Grade 304 Stainless Steel DIN 7985 Low Profile Fasteners

Size:M2-M36

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

Treatment/Finishing: Brushing、Anodizing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

Slim head (low-profile) machine screws are increasingly specified where reduced head height, flush appearance, and confined clearance are required. This short review synthesizes material performance, geometric considerations, and quality controls with practical recommendations from TAIMING Hardware, to help engineers and procurement teams choose and validate fasteners for industrial applications.

Material and mechanical attributes

Slim head machine screws are commonly produced in austenitic stainless steels (A2/304, A4/316) and carbon steels with protective platings. Typical metric sizes range from M2 to M8 with lengths from ~4 mm to 40 mm for general assemblies; metric thread pitches and class fits should follow standard metric practice. Important mechanical properties to compare include tensile strength, yield, and hardness (Rockwell or Vickers), plus torsional capacity for driver selection. For corrosive or outdoor environments, TAIMING recommends 316/A4 or higher corrosion-resistant options and applying surface finishes such as zinc-nickel passivation or antibacterial coatings where necessary.

Dimensional and functional standards

Slim head geometry reduces head projection and is ideal for low-profile assemblies and electronics enclosures. Designers should verify head diameter, bearing surface, drive type (Phillips, Pozidriv, Torx) and engagement depth to avoid cam-out and stripping. Instead of relying on a single reference, specify “metric slim head machine screw to applicable ISO/DIN metric standards” and include required tolerances, surface treatment, and grade in procurement documents to speed compliance checks.

Quality assurance and testing (TAIMING recommendations)

TAIMING advises suppliers to provide mill certificates and batch traceability for every shipment. Recommended QA tests include: tensile and proof-load testing, salt spray (corrosion) testing for plated parts, and driver-torque/strip torque validation. For high-reliability sectors (automotive, medical devices), TAIMING suggests integrating IATF/ISO quality records and showing process capability (Cp/Cpk) for critical dimensions to accelerate vendor qualification.