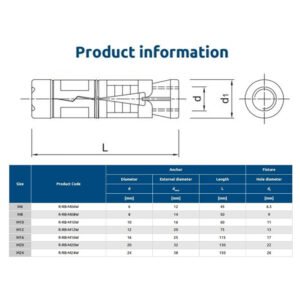

Rawal Bolt Grade 8.8 for Heavy-Duty Anchoring – ISO Standard Concrete Expansion Fastener

Size:M6-M20

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

Treatment/Finishing: Brushing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

Rawal bolts, often used as expansion anchors in structural concrete, have become a critical fastener in modern construction and heavy industrial installation. Designed to resist both shear and tensile loads, Rawal bolts offer superior holding power in solid base materials such as reinforced concrete, brick, and stone. TAIMING, a precision fastener manufacturer based in China, recommends using Rawal bolts conforming to DIN standards with carbon steel Grade 8.8 for high-load applications.

From a technical standpoint, the success of Rawal bolts lies in their ability to expand and grip the base material firmly when torque is applied. This mechanism ensures load transfer is stable over time, even under vibration, temperature changes, or dynamic stresses. At TAIMING, our engineering team emphasizes thread precision, anti-corrosion coating options (e.g., zinc-plated or hot-dip galvanized), and consistent mechanical testing to ensure performance meets international standards.

A common challenge faced by engineers is anchoring into aged or slightly brittle substrates. In such cases, TAIMING advises the use of long shank Rawal bolts with larger embedded depth, offering better stress distribution. Moreover, for machinery baseplates and steel column installations, our tests show that Grade 8.8 bolts with coarse metric threads deliver better torque retention than finer threads.

We also provide clients with technical drawings, pull-out resistance data, and custom manufacturing options based on project load specifications. For example, Rawal bolts installed at a depth of 60mm into C30 concrete achieve pull-out values exceeding 15kN — a critical factor in equipment anchoring and seismic safety planning.

TAIMING’s Rawal bolts are trusted by construction contractors, equipment installers, and MRO engineers across Southeast Asia and North America. With full compliance to ISO 898-1 and DIN 529, we guarantee strength, consistency, and professional support from prototype to delivery.