Pan Head Tapping Screws wooden bed furniture mdf screw

Size:M2-M10

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

Treatment/Finishing: Brushing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

Pan head tapping screws are widely used in applications requiring strong, self-threading capability without the need for pre-tapped holes. Featuring a rounded, low-profile head with a flat bearing surface, these screws distribute clamping force evenly, making them ideal for sheet metal, plastic, and light-gauge assemblies.

Available in sizes ranging from M2.2 to M6.3, these screws are often made from hardened carbon steel or stainless steel grades like AISI 304 and 410 for enhanced corrosion resistance and tensile strength. Common drive types include Phillips, Torx, and hex socket (allen head), depending on the application’s torque requirements and installation environment.

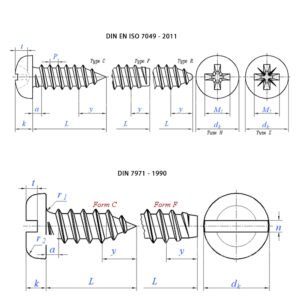

Surface treatments such as zinc plating, black oxide, and ruspert coating further improve resistance to wear and environmental exposure. Many pan head tapping screws conform to standards like DIN 7981 or ISO 7049, ensuring compatibility across global markets and consistent thread quality.

The self-tapping design includes sharp cutting threads or a Type B point, enabling easy penetration into base materials and reliable thread engagement. These screws are essential for manufacturers seeking cost-effective, high-performance fastening solutions in the electronics, appliance, and automotive sectors.