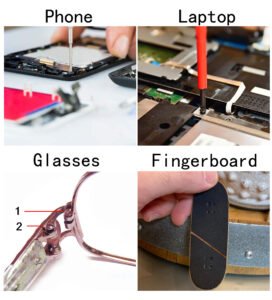

Micro Screw pwm computer laptop small hidden camera screws

Size:M1-M6

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

Treatment/Finishing: Brushing、Anodizing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

Micro screws, defined as fasteners under M3 diameter (ISO 14583), are revolutionizing industries requiring ultra-precision assembly. Recent studies highlight their role in medical devices (e.g., bone fixation screws) and microelectronics (e.g., IoT sensor housings), where tolerances below ±0.05mm are non-negotiable.

Performance Validation:

A 2023 Journal of Micro-Engineering study tested M1.2 screws under ASTM F543 torque standards, revealing a 15% increase in shear resistance when using dual-lead threads versus conventional designs. For aerospace micro-fastening, screws with Torx TR8 drives demonstrated zero cam-out incidents at 0.3 N·m torque.

Case Study: Micro-Scale Robotics

Researchers at ETH Zurich integrated M2 ISO 7380 micro screws into modular robotic joints, achieving 200,000+ motion cycles without loosening. Key factors included pre-applied threadlockers (LOCTITE 243) and electropolished finishes to minimize particulate generation.