Hex Nuts High Quality Steel Black Screw Manufactur Hexagonal Nuts

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

Treatment/Finishing: Brushing、Anodizing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

Hex nuts, particularly those manufactured in compliance with DIN 934 and ISO 4032 standards, are foundational components in modern mechanical assemblies. These six-sided fasteners, designed for secure engagement with standard bolts and machine screws, offer a combination of strength, reliability, and dimensional consistency. Commonly available in Grade 8, A2-70 stainless steel, and Class 10, hex nuts are engineered for diverse applications ranging from heavy-duty structural connections to precision industrial machinery.

The thread pitch, material hardness, and coating type—such as zinc-plated, black oxide, or hot-dip galvanized—play critical roles in determining their resistance to vibration, corrosion, and load-bearing capacity. For example, Grade 8 hex nuts with coarse threads are preferred in automotive assemblies due to their higher tensile strength, while stainless steel variants are optimal for marine and outdoor environments.

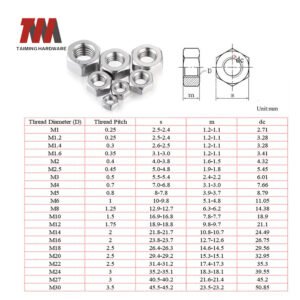

Dimensions typically range from M3 to M48 in metric systems, and #6 to 1-1/2″ in imperial, with custom sizing available per OEM requirements. Precision-machined threads ensure optimal mating with bolts, minimizing torque loss and reducing risk of failure under load. Hex nuts can be paired with lock washers or nyloc inserts to enhance resistance to loosening under dynamic loads.

As a specialized manufacturer and global supplier of fasteners, we provide high-volume production of hex nuts in standard and custom specs, ensuring compliance with RoHS, REACH, and ASTM standards. Each batch undergoes rigorous quality checks, including thread gauge testing and salt spray corrosion analysis.

In high-integrity fastening systems, the choice of hex nut is not incidental. It’s a calculated decision driven by performance metrics, environmental compatibility, and industry-specific requirements—where mechanical fastening efficiency is critical to operational safety and durability.