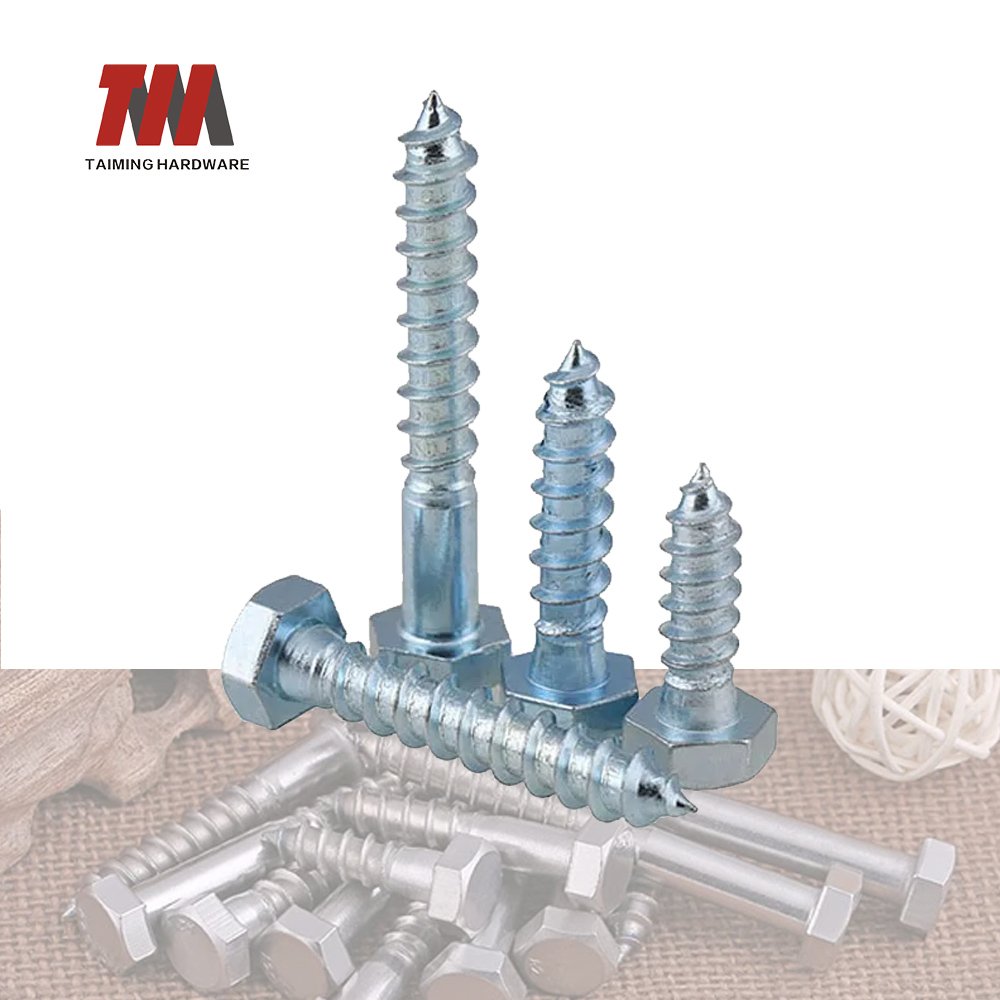

Hex Head Tapping Screws lag bolts trim thread forming screw

Size:M2-M10

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

Treatment/Finishing: Brushing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

Hex head self-tapping screws are widely used in construction, automotive repair, and machinery. Unlike standard screws, they cut their own threads into metal, wood, or plastic, eliminating the need for pilot holes. The hexagonal head provides strong torque transfer, ensuring a secure and reliable connection.

These screws are commonly produced in carbon steel or stainless steel. Surface finishes such as zinc plating or black oxide are applied to improve corrosion resistance and durability. Stainless steel is often chosen for outdoor or chemical environments, while zinc-plated carbon steel offers a cost-effective option for indoor use.

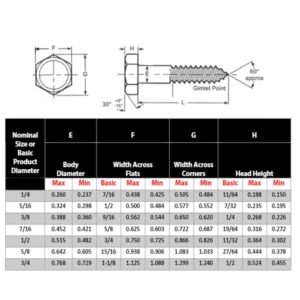

TAIMING, a trusted screw and bolt manufacturer, highlights that choosing the right specification is critical. Thread design, base material hardness, and tightening torque all affect joint performance. Fine pitch threads with sharp points work best for thin sheet metal, while coarse threads are more efficient in thicker substrates.

Ease of installation is another key advantage. Hex head self-tapping screws can be driven quickly with common hex drivers or impact tools, saving time in production lines. TAIMING recommends proper lubrication during installation to reduce friction, protect surfaces, and extend tool life.

In practice, these screws are used in sheet metal fabrication, furniture assembly, electronics, and automotive components. Their ability to combine strength with efficiency makes them an essential fastener across industries.

In conclusion, hex head self-tapping screws are not simple hardware items but engineered solutions. By selecting the right material, finish, and thread geometry, users can maximize performance and durability. TAIMING’s expertise provides valuable guidance for businesses seeking reliable and cost-effective fastening solutions that deliver long-term stability and safety.