Hex Flange Bolts din 6921 screws and fasteners

Size:M6-M20

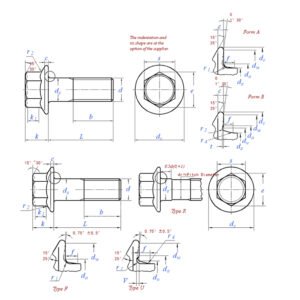

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

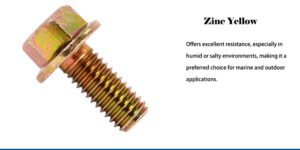

Treatment/Finishing: Brushing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

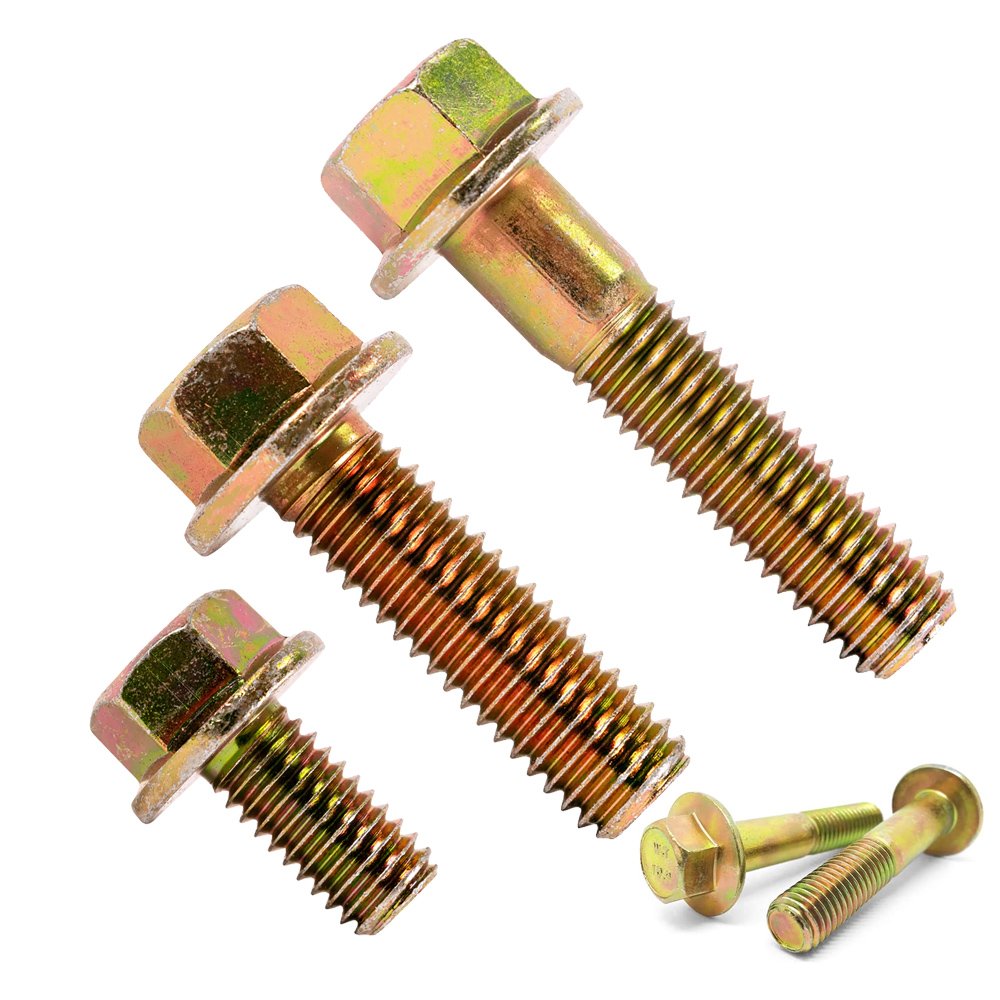

Hex flange bolts are widely recognized for their integrated washer-like flange under the head, which distributes clamping force across a broader surface area. This feature eliminates the need for a separate washer and ensures more secure fastening, especially in high-vibration environments like automotive assembly and heavy equipment manufacturing.

These bolts are often manufactured in Grade 8.8 or 10.9 carbon steel, offering a balance between tensile strength and cost-effectiveness. Depending on application requirements, surface finishes such as zinc plated, black oxide, or hot-dip galvanized are applied to enhance corrosion resistance and appearance. Most flange bolts conform to DIN 6921 or ISO 1665 standards, ensuring consistent dimensions and mechanical properties across global supply chains.

From TAIMING’s perspective, selecting the appropriate thread pitch and head diameter is critical when sourcing hex flange bolts for load-sensitive assemblies. TAIMING’s engineering team recommends using fine-threaded hex flange bolts in precision applications where loosening under dynamic stress must be minimized. In contrast, coarse-threaded bolts are more suitable for fast installation in general construction settings.

TAIMING also emphasizes the importance of traceability and quality consistency. Their in-house quality control system, supported by CNC measurement tools and salt-spray testing, ensures that every batch of hex flange bolts meets client-specific standards. We have noted that improper flange diameter or coating thickness may compromise torque efficiency and result in surface galling—especially in stainless steel versions (A2-70, A4-80).