GRUB SCREWS CUP POINT HEX SOCKET SET SCREW DIN 916 Carbon Steel setscrews Galvanized Machine Screws

Size:M2-M10

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

Treatment/Finishing: Brushing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

Set screws, often classified under machine screws, are designed to fasten an object within or against another object—most commonly used to secure pulleys, collars, and gears onto shafts. Unlike traditional fasteners, set screws feature no external head, making them ideal for applications where surface flushness and compact design are essential.

Available in alloy steel (Grade 12.9), stainless steel (A2-70 or A4-80), and brass, these screws typically conform to DIN 913, DIN 914, or ISO 4026 standards. Common drive types include hex socket (Allen head), slotted, or Torx, allowing for high torque transmission in limited space.

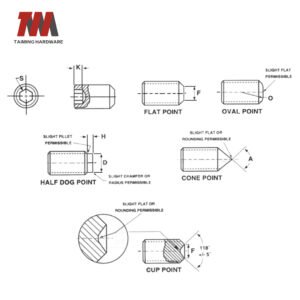

Set screws come with various tip types—flat point, cone point, and cup point being the most widely used. Cup point set screws provide strong holding force with minimal shaft damage, while cone point types offer precise alignment for permanent applications.

Frequently used in automotive assemblies, industrial machinery, and precision instruments, set screws ensure axial retention without requiring through-hole fastening. Their compact form, high-grade material options, and precision threading make them a critical component in mechanical and electrical engineering designs.