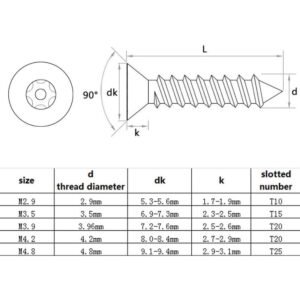

Flat Head Tapping Screws DIN Standard | Self-Drilling Steel Grade

Size:M2-M10

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

Treatment/Finishing: Brushing、Anodizing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

Flat head tapping screws are a critical fastening solution in precision metalworking, HVAC systems, and panel assembly. Designed with a countersunk head that sits flush with the surface, these screws offer both aesthetic finish and functional stability. The self-tapping feature allows direct penetration into metal or plastic without the need for pre-drilling, reducing labor time and improving installation efficiency.

TAIMING, a professional manufacturer and global supplier based in China, recommends using flat head tapping screws made from hardened carbon steel or A2 stainless steel for long-term structural reliability. When exposed to corrosive environments, TAIMING suggests applying a zinc-plated or black phosphate surface treatment, depending on moisture exposure and electrical requirements.

Compliant with DIN 7982 and ISO 7050 standards, TAIMING’s flat head tapping screws are manufactured under strict dimensional tolerance and thread accuracy. These standards ensure optimal thread-forming performance in both thin-gauge metals and thermoplastics. In applications where thermal expansion or vibration is a concern—such as control cabinets, enclosures, or ventilation ducts—TAIMING advises selecting screws with full-threaded shanks and deeper drive recesses for consistent torque performance.

Industrial buyers and OEM engineers often overlook the importance of proper screw geometry. TAIMING’s engineering team recommends evaluating factors such as thread angle, point type (Type AB or Type B), and shaft diameter tolerance, especially when screws are used in automated screwdriving systems.

In summary, flat head tapping screws are more than basic fasteners—they are engineered components that affect structural integrity, production efficiency, and lifecycle costs. TAIMING continues to support clients across North America and Southeast Asia by offering customized solutions, technical consultation, and reliable supply for bulk orders.