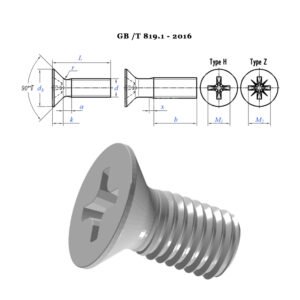

Flat Head Machine Screws Grade 8.8 ISO 7046 Countersunk Precision Fasteners

Size:M2-M10

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

Treatment/Finishing: Brushing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

Flat head machine screws are designed for applications where a smooth, flush surface is essential after fastening. Manufactured under standards such as ISO 7046 or DIN 965, these screws feature a countersunk head and are commonly used in sheet metal, electrical enclosures, and precision equipment. Available in metric and imperial sizes, typical grades include Grade 8.8 or 10.9 for carbon steel, and A2-70 or A4-80 for stainless steel variants.

The flat head design allows the screw to sit level with the surface, improving both safety and aesthetics in applications where protruding heads are undesirable. Finishes such as zinc plating, black oxide, and nickel coating are applied to enhance corrosion resistance. Thread types include fine and coarse pitch, often used in electronic or automotive assemblies. The screws can also be paired with matching tapped holes or machine nuts for secure fastening.

This fastener type is especially critical in aerospace, robotics, and precision machinery where dimensional accuracy and surface integration are non-negotiable.