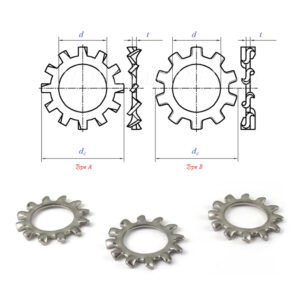

External Tooth Lock Washer DIN 6797 Type A for Anti-Vibration Assemblies

Manufacturing standard:ISO, GB, JIS, DIN, BS and ANSI standards, or drawings provided by customers.

Materials: iron, carbon steel, alloy steel, copper, stainless steel, plastics, high-temperature alloy, copper alloy, nickel-base alloy, high-strength alloy, corrosion-resistant alloy, etc.

Process: cold heading, punching, turning, milling, wire cutting, etc.

Treatment/Finishing: Brushing、Anodizing、Zinc Plated、Nickel Plated、Sn Plated.

Requirements: No Burrs、Scratches、Dents、Pits

Application: Structural Steel; Metal Building; Oil&Gas; Tower&Pole; Wind Energy; Mechanical Machine; Automobile: Home Decorating

Packing:bulk in cartons (25kg Max.)+wood Pallet or according to customer special demand

The external tooth lock washer is a critical component in securing fastener assemblies against loosening due to vibration or dynamic load. Featuring outward-protruding serrations, this washer exerts greater holding force by embedding into the mating surface, creating resistance against rotational movement. Among its primary applications are automotive systems, electrical equipment, machinery bases, and high-vibration structural joints.

These washers are commonly manufactured in stainless steel Grade A2, Grade A4, carbon steel, or spring steel, with surface finishes like zinc plating, black oxide, and passivation to enhance corrosion resistance and electrical conductivity. The DIN 6797 standard—specifically Type A (external teeth)—is widely recognized in global specifications, ensuring dimensional precision and compatibility across various fastener systems. Sizes typically range from M2 to M24, offering versatility across metric bolt dimensions.

From a mechanical standpoint, external tooth lock washers provide superior locking performance compared to plain washers by increasing friction under the bolt head or nut. This property makes them suitable for use in dynamic assemblies where consistent preload is critical, especially in bolted joints exposed to thermal cycling or mechanical shock.

As a manufacturer and global supplier, we offer custom and standard external tooth lock washers with options for bulk packaging, private labeling, and third-party testing. Our in-house tooling capabilities allow us to meet specialized demands for tooth angle, washer thickness, and surface roughness based on application-specific requirements.