Product Testing Procedures

We follow precise and efficient screw and bolt manufacturing processes – from wire drawing, cold forging, thread rolling, to heat treatment and surface coating. Each step ensures high strength, durability and reliable industrial performance. Here we will introduce you to the core processes.

Raw material testing

Quality starts with the right materials. We subject every batch of wire to rigorous raw material inspection – checking hardness, composition and surface condition – to ensure the consistency and durability of the screws and bolts we produce.

Dimensional Inspection

To ensure precise fit and function, each screw and bolt undergoes dimensional inspection using calibrated tools. We check length, diameter, thread pitch, and tolerances to meet exact specifications and industry standards.

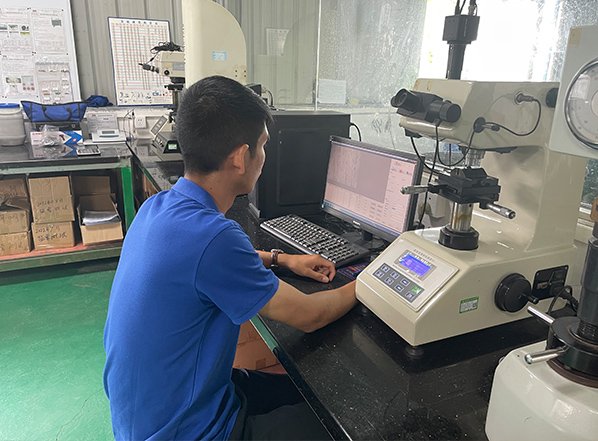

Hardness Testing of Raw Material

To ensure strength and performance, we perform hardness testing on all incoming wire. This step verifies that the material meets the required mechanical properties before it goes into screw and bolt production.

Bolt Torque Testing

We conduct torque tests to ensure that each bolt reaches the required tightening force, ensuring that it has good load-bearing and safety performance in actual use.

Salt Spray Test

Salt spray testing is to ensure the long-term corrosion resistance of the product. Our screws and bolts are all subjected to salt spray testing. This test simulates harsh environments and verifies the durability of the surface coating to ensure its reliable performance.

Optical Inspection for Screws and Bolts

We use optical inspection systems to detect surface defects, dimensional errors, and thread issues with high precision. This ensures every screw and bolt meets strict quality standards before packaging.