FMEA in Fastener Manufacturing — How Taiming Hardware Prevents Failures

FMEA in Fastener Manufacturing — How Taiming Hardware Uses FMEA to Prevent Problems

At Taiming Hardware we treat reliability as part of our product promise. Failure Mode and Effects Analysis (FMEA) is one of the practical tools we use to find potential problems early — before they reach customers. Below we explain our approach, training and examples so procurement teams can see how we control risk across screws, bolts and related fasteners.

What is FMEA and why it matters for fasteners

FMEA (Failure Mode and Effects Analysis) is a structured method for identifying possible failure modes within a product or process, estimating their effects and prioritizing actions to reduce risk. For fasteners, common failure modes include dimensional non-conformity, incorrect heat treatment, thread damage and plating defects. Addressing these risks early saves time, cost and customer disruption.

How we run FMEA at Taiming Hardware

- Cross-functional workshops. We run FMEA sessions with design, production, QA and maintenance so every perspective is covered.

- Data-driven scoring. Severity, Occurrence and Detection scores are based on historical data, inspection results and supplier history.

- Action tracking. Each high-risk item has a specific corrective or preventive action, an owner and a target date — we monitor progress in weekly control meetings.

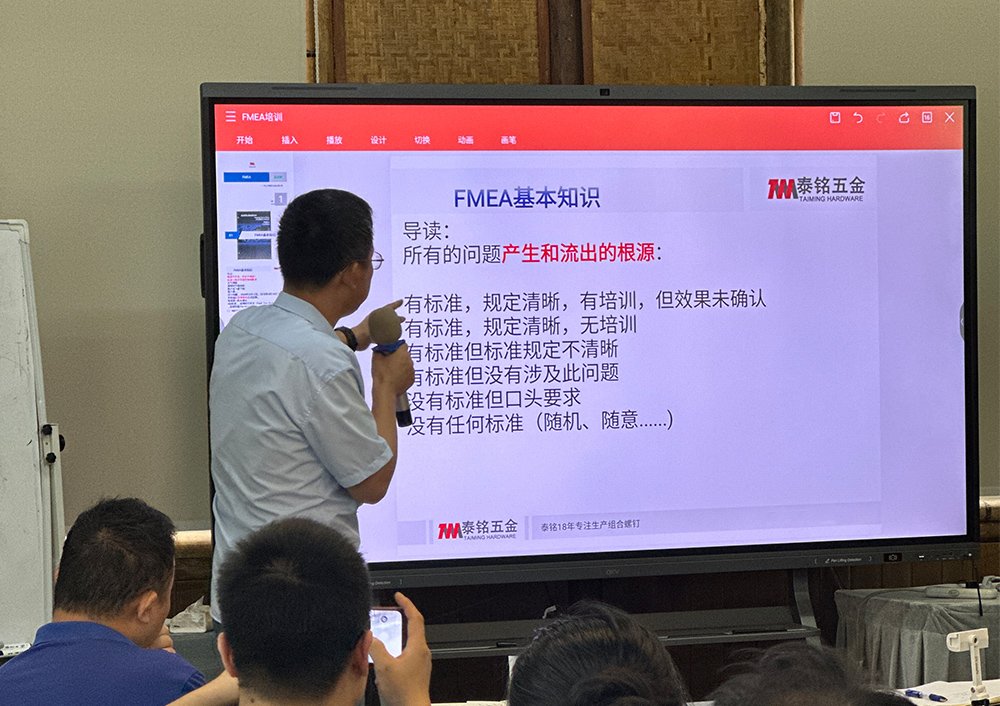

- Training & competence. We run practical workshops (see photos) so operators and supervisors can spot early signs of problems on the line.

Practical FMEA examples for screws & bolts

Here are condensed examples that show how we translate analysis into controls:

- Thread pitch error (dimensional): Root cause — worn thread die. Control — die life tracking + in-process gauge checks. Result — reduction in rework rates by planned maintenance.

- Hardness below spec (mechanical strength): Root cause — cooling irregularity after heat treatment. Control — thermocouple mapping, rework limits and batch hold for metallurgical verification.

- Plating adhesion failure (corrosion resistance): Root cause — improper pre-treatment. Control — pH and conductivity checks before plating bath use, plus random salt spray verification.

How FMEA supports our customers

Buyers working with Taiming Hardware gain three tangible benefits:

- Fewer surprises: fewer defects and less production downtime at customers’ end.

- Faster root cause response: if a problem occurs, our FMEA points to likely causes, speeding corrective action.

- Transparent quality records: we share relevant FMEA results, inspection plans and improvement logs with customers under NDA or as part of PPAP / quality documentation packages.

Want proof? Ask for our FMEA summary

If you are evaluating suppliers, ask Taiming Hardware for a summary FMEA related to the product family you buy (for example: hex bolts, machine screws or welded studs). We will provide a redacted summary showing the top failure modes, current controls and recent improvement results so your technical team can assess alignment with your risk acceptance.

Related products: Hex bolts & fasteners.